Xariir Dhalaalaya Midab Dhakhso Leh Isbeddelka Jaangooyooyinka Qaanso-rogaaleedyo badan leh oo Daabacaha 3D ah oo leh PLA Filament

Tilmaamaha Badeecada

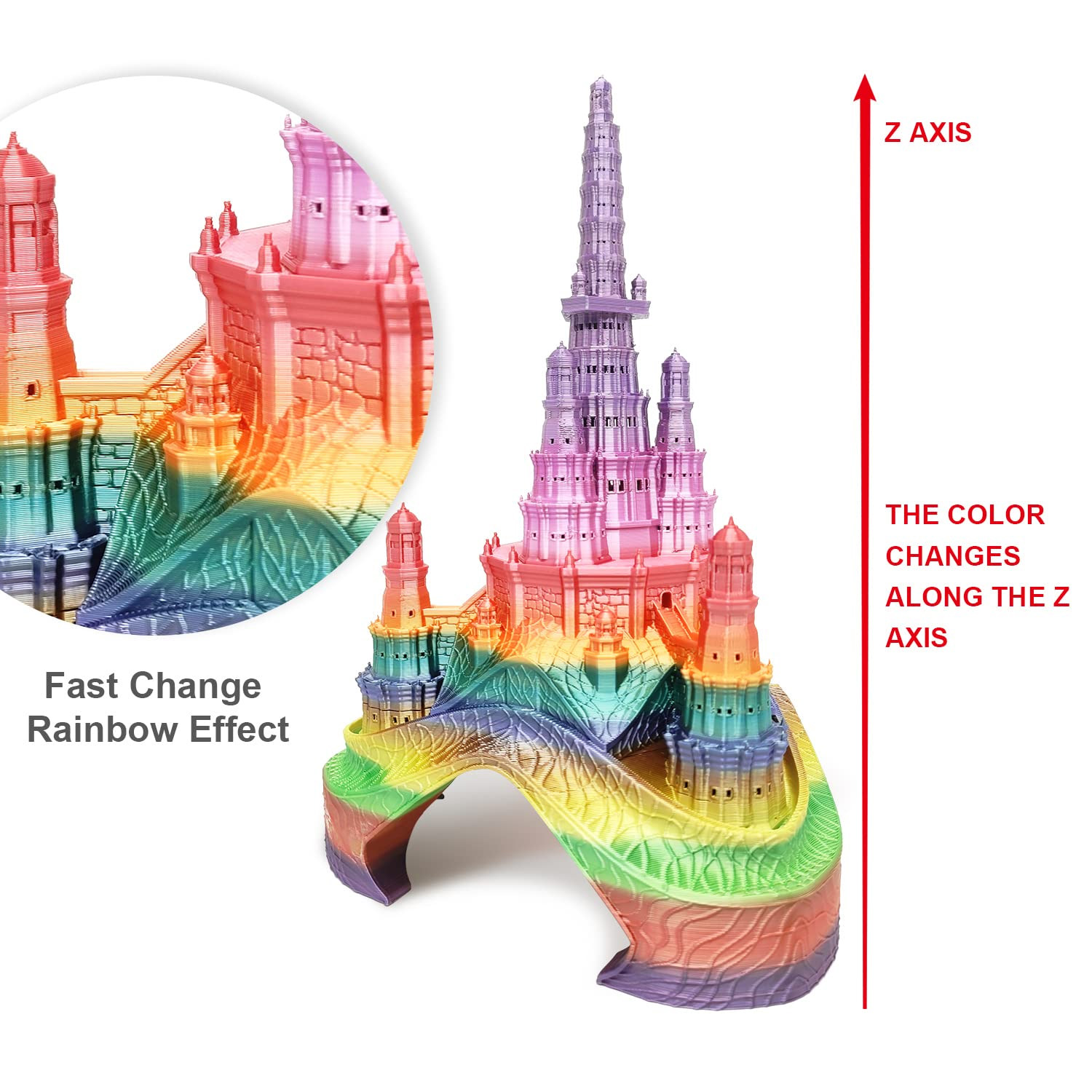

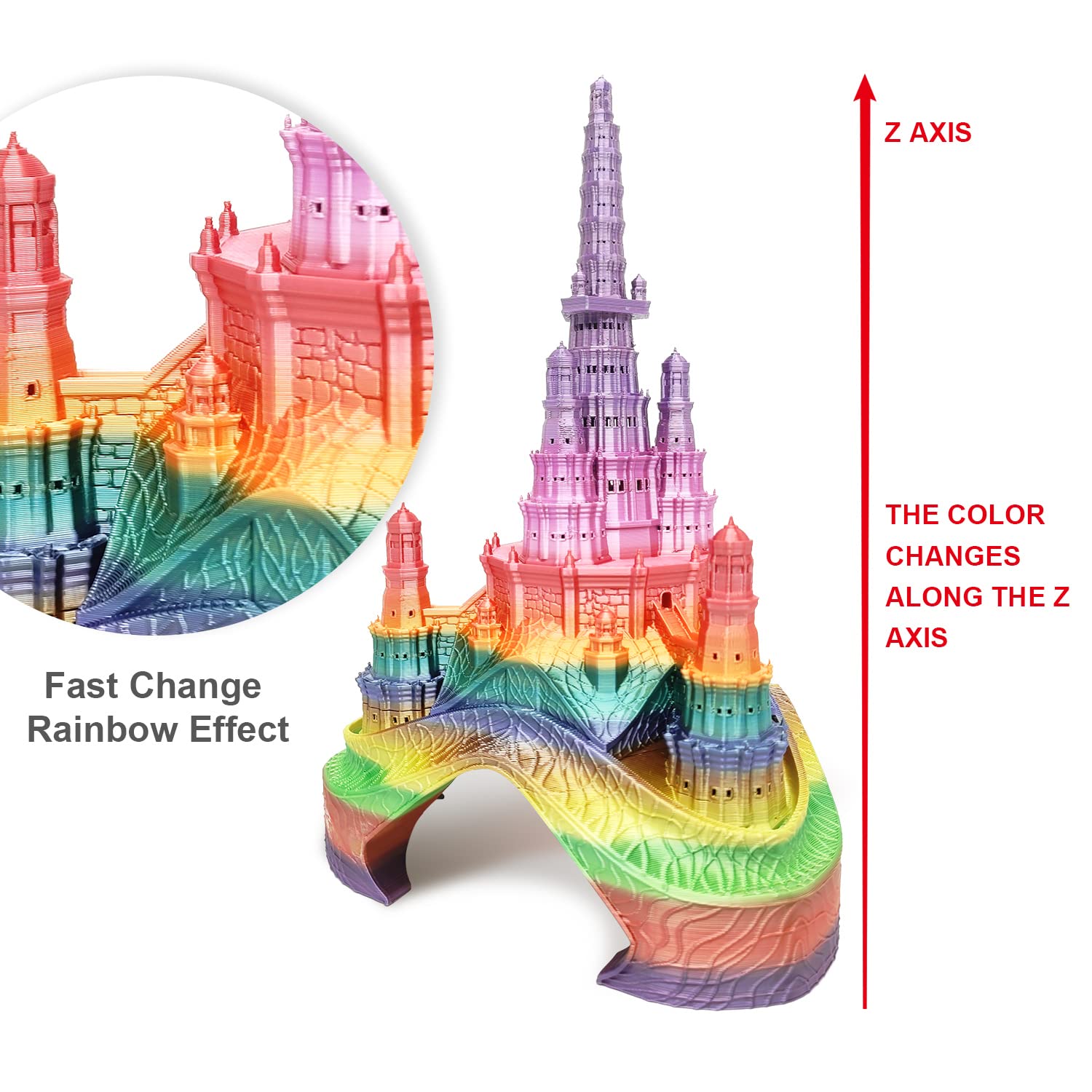

Astaamaha gaarka ah ee xargaha xariirta ee Torwell ee midabada badan leh ee PLA waa saamaynta midabka qaanso roobaadka. Maaddadu waxay ka kooban tahay isku darka PLA iyo walxo kale, taas oo abuurta saameyn midabyo badan leh oo ku saabsan shayga la daabacay, taasoo ka dhigaysa mid ku habboon sameynta farshaxanka iyo walxaha qurxinta. Intaa waxaa dheer, xargaha xariirta ee Torwell ee midabada badan leh ee PLA waxay leedahay sifooyin farsamo oo aad u fiican iyo dusha dhalaalaya, taasoo hubinaysa tayada sare iyo isticmaalka waara ee shayga la daabacay.

| Summada | TOrwell |

| Alaab | isku-dhafka polymer-ka Pearlescent PLA (NatureWorks 4032D)) |

| Dhexroorka | 1.75mm/2.85mm/3.0mm |

| Miisaanka saafiga ah | 1 Kg/spool; 250g/spool; 500g/spool; 3kg/spool; 5kg/spool; 10kg/spool |

| Miisaanka guud | 1.2Kg/spool |

| Dulqaad | ± 0.03mm |

| Dhererka | 1.75mm(1kg) = 325m |

| Deegaanka Kaydinta | Qallalan oo hawo leh |

| Dejinta Qallajinta | 55˚C muddo 6 saacadood ah |

| Agabka taageerada | Ku mari Torwell HIPS, Torwell PVA |

| Ansixinta Shahaadada | CE, MSDS, Reach, FDA, TUV iyo SGS |

| La jaan qaadaya | Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, Bambu Lab X1, AnkerMaker iyo daabacayaasha kale ee FDM 3D |

Bandhigga Moodeelka

Midabada Qaanso roobaad ee Birta Xariirta ah ee Gaarka ah:

Waa Midabka Gradient-ka, Qiyaastii 3 - 5 Mitir Midabka ayaa isbeddela, Waa mid aan kala sooc lahayn in laga beddelo hal midab ilaa mid kale; Waa wax cajiib ah in la daabaco Midabo badan oo Gaar ah Shay ku jira hal Filament Spool ah oo taageera Hal-abuurkaaga iyo Naqshadeyntaada Adduunka Daabacaadda 3D si aad u wanaagsan!

Shahaadooyinka:

ROHS; GAAR; SGS; MSDS; TUV

| Cufnaanta | 1.21 g/cm3 |

| Tusmada Socodka Dhalaalaya (g/10 daqiiqo) | 4.7(190℃/2.16kg) |

| Heerkulka Khalkhalka Kulaylka | 52℃, 0.45MPa |

| Xoogga Tijaabada | 72 MPa |

| Kordhinta Nasashada | 14.5% |

| Xoogga Dabacsanaan | 65 MPa |

| Modulus-ka dabacsan | 1520 MPa |

| Xoogga Saamaynta IZOD | 5.8kJ/㎡ |

| Waara | 4/10 |

| Daabacaad la'aanta | 9/10 |

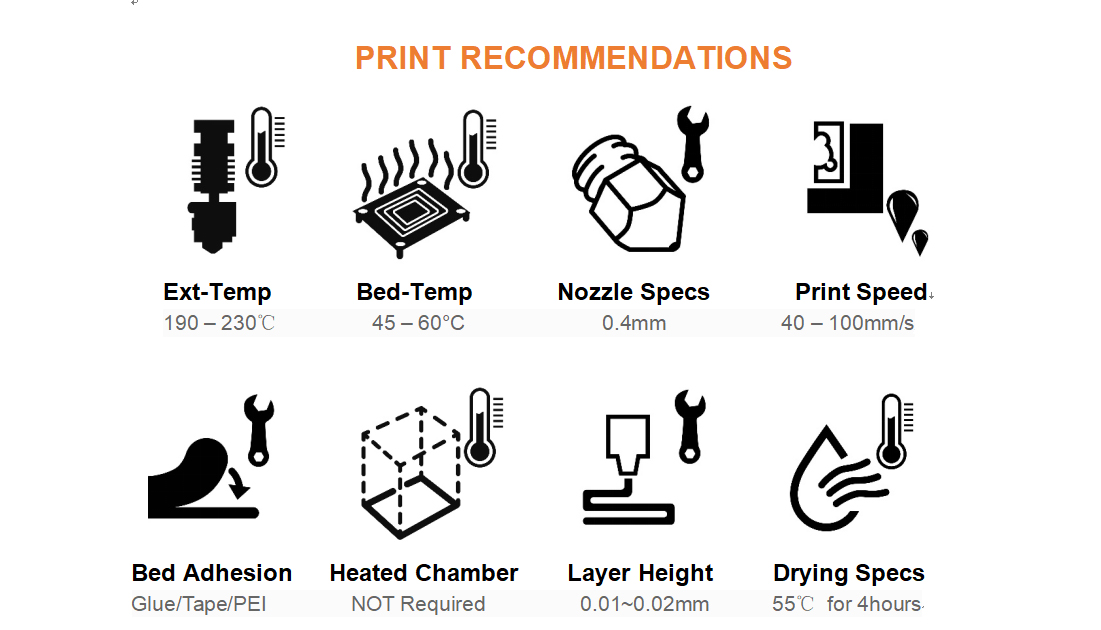

1. Si loo gaaro saameynta daabacaadda ugu fiican iyadoo la isticmaalayo fiilada xariirta PLA ee midabada badan leh, waxaa lagu talinayaa in la isticmaalo dhexroorka afka oo ah 0.4 mm ama ka yar. Dhexroorka afka oo yar ayaa gaari kara faahfaahin iyo tayo sare oo wanaagsan. Heerkulka daabacaadda ee lagu taliyay waa inta u dhaxaysa 200-220°C, iyadoo heerkulka sariirta uu u dhexeeyo 45-65°C. Xawaaraha daabacaadda ugu fiican waa qiyaastii 50-60 mm/s, dhererka lakabkuna waa inuu u dhexeeyaa 0.1-0.2 mm.

2. Hubi inaad hagaajiso dhammaadka fiilada ka dib mar kasta oo la isticmaalo, sida inaad geliso dhammaadka xorta ah ee fiilada godka si aad uga fogaato in fiilada la isku dhejiyo marka xigta la isticmaalo.

3. Si aad u dheereyso cimriga fiiladaada, fadlan ku kaydi bac qalalan oo xiran ama sanduuq.

| Heerkulka Qalabka Dab-damiska (℃) | 190 - 230℃Lagu taliyay 215℃ |

| Heerkulka sariirta (℃) | 45 – 65°C |

| NoCabbirka jajabka | 0.4mm |

| Xawaaraha Marwaxad | 100% |

| Xawaaraha Daabacaadda | 40 - 100mm/s |

| Sariir Kulul | Ikhtiyaar ah |

| Dusha Dhismaha ee lagu taliyay | Muraayad leh xabag, Warqad maaskaro, Cajalad Buluug ah, BuilTak, PEI |

Talooyin Daabacaadda:

1) Si loo gaaro saameynta daabacaadda ugu fiican iyadoo la isticmaalayo fiilada xariirta PLA ee midabada badan leh, waxaa lagu talinayaa in la isticmaalo dhexroorka afka oo ah 0.4 mm ama ka yar. Dhexroorka afka oo yar ayaa gaari kara faahfaahin iyo tayo sare oo wanaagsan. Heerkulka daabacaadda ee lagu taliyay waa inta u dhaxaysa 200-220°C, iyadoo heerkulka sariirta uu u dhexeeyo 45-65°C. Xawaaraha daabacaadda ugu fiican waa qiyaastii 50-60 mm/s, dhererka lakabkuna waa inuu u dhexeeyaa 0.1-0.2 mm.

2) Hubi inaad hagaajiso dhammaadka fiilada ka dib mar kasta oo la isticmaalo, sida inaad geliso dhammaadka xorta ah ee fiilada godka si aad uga fogaato in fiilada ay isku dhegto marka xigta la isticmaalo.

3) Si aad u dheereyso cimriga fiiladaada, fadlan ku kaydi bac qalalan oo xiran ama sanduuq.